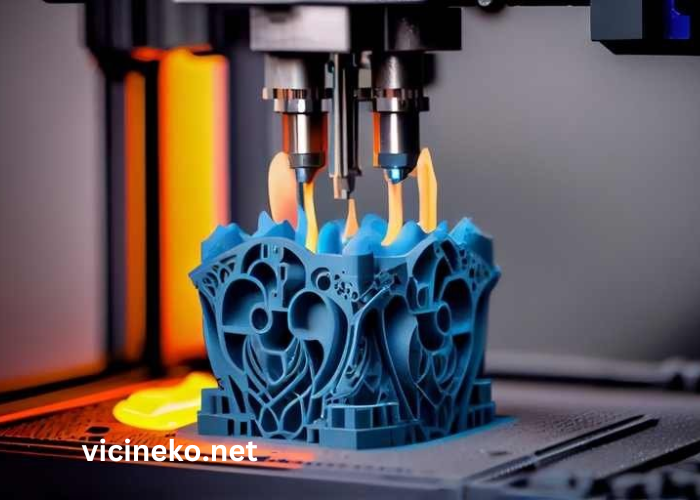

3D printing, also known as additive manufacturing, has come a long way since its inception. Initially confined to prototyping and small-scale production, it has now evolved into a revolutionary tool capable of transforming the way businesses operate across industries. From product design to manufacturing processes, 3D printing offers unprecedented opportunities for innovation, efficiency, and customization. This article explores the potential of 3D printing in driving business innovation and how companies can harness its power for growth and competitiveness.

Introduction: The Role of 3D Printing in Modern Business

In the last decade, 3D printing has emerged as a disruptive force in manufacturing and design. This technology allows for the creation of complex structures, products, and prototypes by layering materials based on digital models. As businesses face increasing demands for speed, customization, and cost-efficiency, 3D printing offers innovative solutions that can meet these challenges. With advancements in materials, processes, and applications, the future of 3D printing in business is incredibly promising.

What is 3D Printing?

3D printing is the process of creating three-dimensional objects from a digital file. The printer reads the design and deposits materials, such as plastic, metal, or resin, layer by layer to build up the object. Unlike traditional manufacturing methods, which often require molds or tooling, 3D printing enables rapid prototyping and low-volume production, making it ideal for custom or on-demand products.

Key Industries Embracing 3D Printing

3D printing is transforming various industries, including aerospace, automotive, healthcare, and consumer goods. In aerospace, it is used to create lightweight, durable components. In healthcare, it enables the development of customized prosthetics and implants. Automotive companies use 3D printing for rapid prototyping and low-volume production of car parts. Consumer goods companies leverage it for personalized products and packaging innovations.

Rapid Prototyping and Product Development

One of the most significant advantages of 3D printing is its ability to accelerate the product development cycle. Traditionally, prototypes would require weeks or months to produce using molds or machining. With 3D printing, prototypes can be created in hours, allowing businesses to test and refine their designs faster. This rapid iteration helps companies bring products to market more quickly, reducing time-to-market and increasing their competitive edge.

Customization and Personalization of Products

3D printing allows businesses to offer highly customized and personalized products without the need for expensive retooling or setting up new production lines. Whether it’s creating custom-fit medical devices or personalized consumer products, the flexibility of 3D printing makes it easier to meet specific customer needs. Personalized products have become a significant trend in industries like fashion, jewelry, and consumer electronics, where 3D printing can produce unique items tailored to individual specifications.

Reducing Manufacturing Costs and Waste

Traditional manufacturing methods often involve significant material waste and high tooling costs. With 3D printing, materials are used efficiently, and only the exact amount needed for the product is consumed. This not only reduces waste but also lowers manufacturing costs, especially for low-volume production. Companies can produce smaller batches of products without the expensive setup costs typically associated with traditional manufacturing.

On-Demand Manufacturing and Supply Chain Flexibility

3D printing enables on-demand manufacturing, allowing businesses to produce products as needed rather than relying on large inventories. This shift reduces storage costs and the risks associated with overproduction. Additionally, 3D printing can streamline supply chains by reducing reliance on traditional suppliers and enabling local, distributed production. As a result, companies can be more agile, responding to market changes or customer demands more quickly.

Enhancing Product Design and Innovation

With 3D printing, designers are no longer constrained by traditional manufacturing limitations. Complex geometries and intricate designs that were previously difficult or impossible to achieve can now be produced with ease. This opens up new possibilities for innovation in product design. Companies can experiment with innovative materials, structures, and functionalities that were not feasible with conventional manufacturing processes.

Sustainability and Environmental Impact

3D printing contributes to sustainability by minimizing waste and reducing energy consumption in manufacturing. Traditional production processes often generate excess material waste, which ends up in landfills. With 3D printing, materials are deposited layer by layer, meaning that only the material needed for the final product is used. Furthermore, 3D printing can reduce the carbon footprint associated with transportation and distribution by enabling local production.

Improving Collaboration and Remote Work

As 3D printing technology becomes more accessible, it is also improving collaboration across teams, particularly in remote or global settings. Designers, engineers, and manufacturers can work together on digital prototypes in real time, regardless of their geographic location. This collaborative approach speeds up the product development process and ensures that all stakeholders are aligned from the outset. Additionally, 3D printers are becoming more compact and affordable, making them accessible to small businesses and entrepreneurs.

The Role of Materials in 3D Printing

The evolution of 3D printing materials has expanded the range of industries that can benefit from this technology. Materials such as metals, ceramics, and biocompatible substances are now being used to create products that require higher strength, durability, or specialized properties. The development of new materials will continue to enhance the capabilities of 3D printing, making it applicable for an even broader range of applications, from aerospace to medical devices.

Intellectual Property and 3D Printing

As 3D printing becomes more widespread, intellectual property (IP) concerns are also becoming increasingly important. The ability to replicate designs quickly and easily raises questions about copyright infringement, patent protection, and counterfeit goods. Businesses must implement strategies to protect their intellectual property in the digital realm, ensuring that their innovations are not copied or exploited without authorization. Blockchain technology may provide solutions for tracking and securing digital designs.

Challenges in Adopting 3D Printing for Business

Despite its potential, 3D printing adoption presents several challenges for businesses. High initial investment costs, the need for specialized knowledge, and limited material options are some of the barriers that companies must overcome. Additionally, the quality and consistency of 3D printed products can sometimes vary, particularly with low-cost printers. As technology improves and becomes more accessible, these challenges will diminish, but businesses must carefully evaluate their readiness to implement 3D printing into their operations.

The Future of 3D Printing in Business

The future of 3D printing in business looks bright, with continued advancements in technology, materials, and applications. The rise of more affordable, efficient, and user-friendly 3D printers is enabling smaller businesses to tap into the benefits of this technology. In the coming years, we can expect to see 3D printing play an even more significant role in sectors such as healthcare, construction, and fashion, creating new opportunities for innovation and entrepreneurship.

Conclusion: Unlocking Innovation Through 3D Printing

3D printing is revolutionizing the way businesses approach design, manufacturing, and product development. With its ability to drive customization, reduce costs, and improve sustainability, 3D printing offers unprecedented opportunities for innovation across a wide range of industries. As technology continues to evolve, the potential of 3D printing to disrupt traditional business models and create new pathways for growth will only increase. For businesses looking to stay competitive, embracing 3D printing is no longer just an option—it’s a strategic imperative.